SS ButterFly Valve

SS ButterFly Valve Specification

- Material

- Stainless Steel (SS)

- Technique

- Casting

- Connection

- Wafer Type

- Shape

- Round

- Head Code

- Standard

- Type

- Manual

- Port Size

- 2 Inch to 12 Inch

- Style

- Butterfly Valve

- Pressure

- PN10/PN16

- Application

- Water, Oil, Gas Flow Control

- Temperature Range

- -20°C to +120°C

- Grade

- SS304 / SS316

- Finish

- Polished

- Leakage

- Bubble-tight

- Seat Material

- EPDM / PTFE

- Disc Material

- Stainless Steel

- Body Material

- Stainless Steel

- Operation

- Lever / Gear Operated

- End Connection

- Wafer fit between flanges

SS ButterFly Valve Trade Information

- Minimum Order Quantity

- 3 Pieces

- FOB Port

- By Road

- Payment Terms

- Others

- Supply Ability

- 3 Pieces Per Day

- Delivery Time

- 2 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per standered

- Main Export Market(s)

- Africa

- Main Domestic Market

- All India

About SS ButterFly Valve

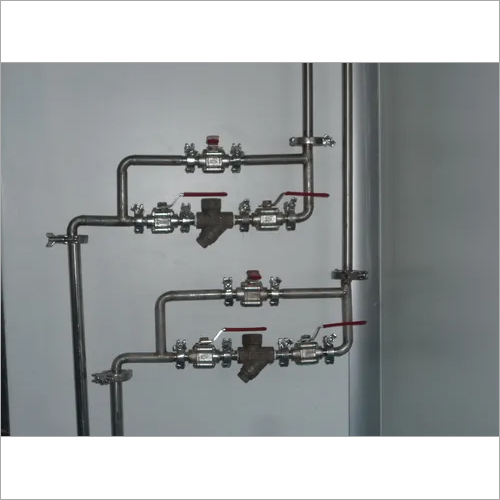

We are listed amongst the renowned organizations in this domain, engaged in offering a superior quality range of SS ButterFly Valve. Used in different industries to control, isolate & regulate the flow of gases, fluids and slurries, this valve is manufactured by our highly experienced professionals using superior quality raw material and most modern technology. In addition, this valve is checked on numerous quality parameters to make certain its faultless finish. We offer this SS ButterFly Valve in different sizes at very nominal price to the clients.

Features:

- Corrosion resistance

- Sturdy construction

- Dimensional accuracy

- High durability

Superior Materials and Versatile Operation

Crafted using stainless steel grades SS304 and SS316, this butterfly valve is designed for durability and corrosion resistance. It features manual operation modeslever or gearfor added flexibility in flow control. The polished surface adds an extra layer of protection and aesthetic appeal while ensuring ease of maintenance.

Reliable Performance and Bubble-Tight Sealing

Equipped with EPDM or PTFE seat materials, the valve guarantees effective bubble-tight sealing to prevent leakage. Its wafer-type end connections enable quick installation between flanges, making it an efficient solution for controlling water, oil, and gas flow. With casting technique and standard head code, the valve offers consistent and reliable performance.

FAQs of SS ButterFly Valve:

Q: How is the SS Butterfly Valve installed in a pipeline system?

A: The SS Butterfly Valve is installed using its wafer-type end connection, which fits securely between standard flanges. This makes the installation process straightforward and compatible with common piping systems in water, oil, and gas applications.Q: What are the benefits of using EPDM or PTFE as seat materials in this valve?

A: EPDM and PTFE seat materials provide excellent sealing, chemical resistance, and durability. EPDM is ideal for water and some chemicals, while PTFE offers superior compatibility with oils and gases, ensuring bubble-tight leakage prevention and long-term performance.Q: When should I choose lever versus gear operation for these butterfly valves?

A: Lever-operated valves are best for quick, manual flow control on smaller sizes (typically up to 6 inches), while gear-operated models are recommended for larger valves (sizes beyond 6 inches) where higher torque is needed for smooth and precise operation.Q: Where can these SS Butterfly Valves be used most effectively?

A: These valves are suited for water, oil, and gas flow control in diverse industries, including municipal waterworks, chemical processing, refineries, and HVAC systems. They are fabricated and supplied across India to suit both industrial and commercial environments.Q: What process is followed in manufacturing these SS Butterfly Valves?

A: Manufactured using casting techniques, the valves undergo precision fabrication, followed by polishing for enhanced finish quality. Each valve is rigorously tested to meet pressure ratings (PN10/PN16) and ensure bubble-tight sealing before being exported or supplied to clients.Q: How does the bubble-tight leakage feature improve flow control?

A: The bubble-tight leakage feature guarantees zero leakage when the valve is closed, resulting in improved safety and efficient isolation of fluids. This enhances operational reliability and safeguards against product losses or environmental hazards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Valves Category

Tee Pattern Diaphragm Valve

Price 4000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Other, Cast Iron / Cast Steel / Stainless Steel

Connection : Other, Flanged Ends

Application : Water, Chemical, Oil, Gas, Industrial Use

Shape : Other, Tee

Back Pressure Valve

Minimum Order Quantity : 02 Pieces

Material : Stainless Steel

Connection : Other, Flanged

Application : Fluid and Gas Control

Shape : Other, Round

Ss Diaphragm Valve

Price 9000 INR / Piece

Minimum Order Quantity : 3 Pieces

Material : Other, Stainless Steel (SS)

Connection : Other, Flanged

Application : Industrial and Chemical Process

Shape : Other, Round

Spray Ball Valves

Price 6000 INR / Piece

Minimum Order Quantity : 03 Pieces

Material : Stainless Steel

Connection : Other, Threaded

Application : CIP (CleaninPlace) systems, pharmaceutical, food and beverage industries

Shape : Other, Round

|

MECHZEAL INTERPHASING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |