Custom Pressure Vessels

Custom Pressure Vessels Specification

- Application

- Industrial, Chemical Processing, Pharmaceutical, Food & Beverage

- Type

- Custom Pressure Vessel

- Material

- Mild Steel, Stainless Steel

- Capacity

- 500-10000 Liter

- Weight

- Custom as per design

- Dimension (L*W*H)

- Custom as per requirement

- Condition

- New

- Mounting Type

- Skid Mounted or Standalone

- Testing

- Hydrostatic & Pneumatic Testing Provided

- Customization

- Yes, as per client specifications

- Connection Type

- Flanged, Threaded, or Welded

- Temperature Range

- -20°C to 300°C (depending on material and design)

- Shape

- Cylindrical, Vertical or Horizontal (as per requirement)

- Corrosion Resistance

- Yes, based on material selection

- Pressure Rating

- Up to 100 bar (customizable)

- Manufacturing Standard

- ASME, IS, or custom codes

- Surface Treatment

- Sand Blasted, Epoxy Coated Available

- Finish

- Painted or Powder Coated

Custom Pressure Vessels Trade Information

- Minimum Order Quantity

- 01 Kilograms

- FOB Port

- By Road

- Payment Terms

- Others

- Supply Ability

- 02 Kilograms Per Week

- Delivery Time

- 2 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per stander-ed

- Main Export Market(s)

- Africa

- Main Domestic Market

- All India

About Custom Pressure Vessels

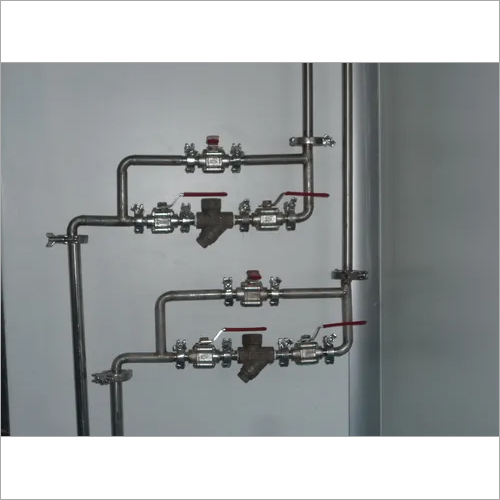

Leveraging upon our rich industry experience, we are offering our clients a wide array of Custom Pressure Vessels. These vessels are manufactured with high accuracy using quality approved raw material and are broadly used in various industries like pharmaceutical, food processing, chemical, oil& gas processing, etc. The offered vessels are highly demanded in the midst of clients due to its superior strength, robust construction, dimensional accuracy and robustness. Furthermore, these Custom Pressure Vessels are accessible with us in different dimensions as per the wants of clients.

Features:

- Dimensional accuracy

- Enhanced durability

- Corrosion resistance

- High strength

Built for Your Application

We construct pressure vessels that suit multiple industries, from chemical processing to pharmaceuticals and food & beverage manufacturing. Each unit is configured to your specificationsshape, mounting, and materialensuring practical integration within your workflow while upholding rigorous quality and safety standards.

Comprehensive Customization

Our vessels are fully customizable by capacity, material, dimensions, and pressure rating, allowing clients to tailor every aspect according to process requirements. Finish options like powder coating or painting, as well as advanced surface treatments, ensure long-lasting performance even in challenging environments.

Stringent Manufacturing and Testing

Each pressure vessel is fabricated under recognized codes such as ASME or IS, or tailored to bespoke standards. Comprehensive hydrostatic and pneumatic tests verify vessel integrity and safety, guaranteeing operational reliability and regulatory compliance for every delivered product.

FAQs of Custom Pressure Vessels:

Q: How are your custom pressure vessels tailored to specific industrial processes?

A: Each vessel is engineered based on your process parameters, including required pressure, temperature range, material preference, and dimensions. You can select from vertical or horizontal cylinders, various mounting types, and surface treatments, ensuring perfect alignment with your application needs.Q: What manufacturing standards do you follow for pressure vessels?

A: Our pressure vessels are manufactured in accordance with leading codes such as ASME and IS. We also offer customization to meet unique client standards, ensuring all vessels fulfill stringent quality, safety, and regulatory requirements.Q: When should I choose a painted or powder-coated finish for my vessel?

A: Your choice depends on the operating environment and desired corrosion resistance. Powder coating typically offers superior chemical and wear resistance, making it ideal for more aggressive settings, while painting can be effective for standard industrial use.Q: Where can these pressure vessels be installed?

A: They are versatile enough for installation at industrial, chemical, pharmaceutical, or food & beverage facilities. Options for skid mounting or standalone units mean they adapt readily to new builds or existing systems across India and for export.Q: What is involved in the testing process prior to delivery?

A: Every pressure vessel undergoes comprehensive hydrostatic and pneumatic testing to certify structural soundness, leak-proof operation, and adherence to safety protocols before being shipped to the client.Q: How does surface treatment improve vessel longevity and usage?

A: Surface treatments like sandblasting and epoxy or powder coating improve resistance against corrosion and chemical exposure, enhancing the operational lifespan and reliability of each vessel in harsh service conditions.Q: What are the benefits of choosing a skid-mounted vessel?

A: Skid mounting offers enhanced stability, easier transport, and simplified integration into existing plant layouts, reducing onsite installation time and minimizing operational disruption.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

MECHZEAL INTERPHASING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |